Improving Product Value With TSM R&D

Smart Manufacturing Factory

1. Eliminating Human-Related Risks and Maintaining Competitive Edge TSMRND provides solutions that eliminate human-related risks—the single greatest threat to enterprises in a rapidly changing production environment. We enable businesses to preserve their unique manufacturing competitiveness and technological leadership.

2. Customized Systems Based on MIP and Production Philosophy Based on the MIP (Manufacturing Intelligence Platform), we support the design of production layouts and systems that reflect each client's unique production philosophy, tailored specifically to their products and current operational status.

3. Energy Optimization and Real-time Monitoring We offer real-time monitoring of energy consumption within production systems. By integrating with the MIP, we enable precise energy efficiency measurement, management, and optimization.

4. High-Quality AI Data Acquisition and DB Construction We specialize in collecting high-quality, practical process AI data and constructing robust databases (DB) to maximize the utility of data within the MIP.

5. LLM-Based MIP for Accessible Operational Intelligence By operating the MIP on a Large Language Model (LLM) basis, we create an environment where even non-experts—not just specialized engineers—can easily monitor production status and identify issues.

6. Streamlining Operations and Reducing Manual Input Our solutions eliminate the need for manual labor in entering production information or conducting unnecessary inventory audits, ensuring that essential production data is verified automatically.

7. Knowledge Internalization and Security Through the MIP, we protect core manufacturing know-how by building a Knowledge Base. This internalizes expertise into the system itself, rather than relying on individuals, thereby ensuring maximum intellectual property security.

8. Data-Driven Decision Making and Talent Leveling MIP shifts the decision-making process from human technicians to data-driven insights. By standardizing performance through system-based intelligence, we resolve risks associated with human resource dependency.

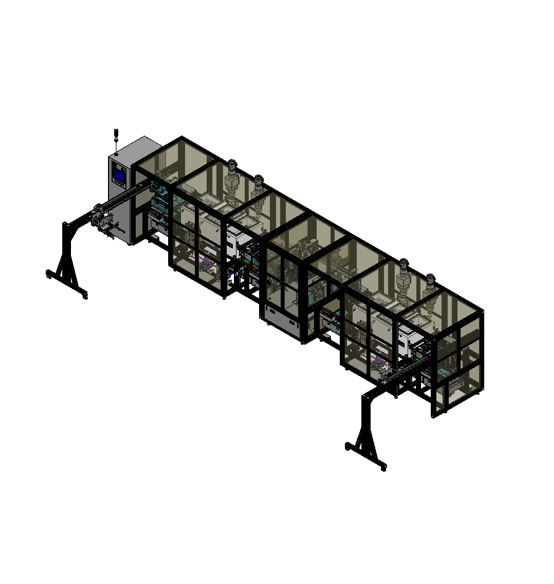

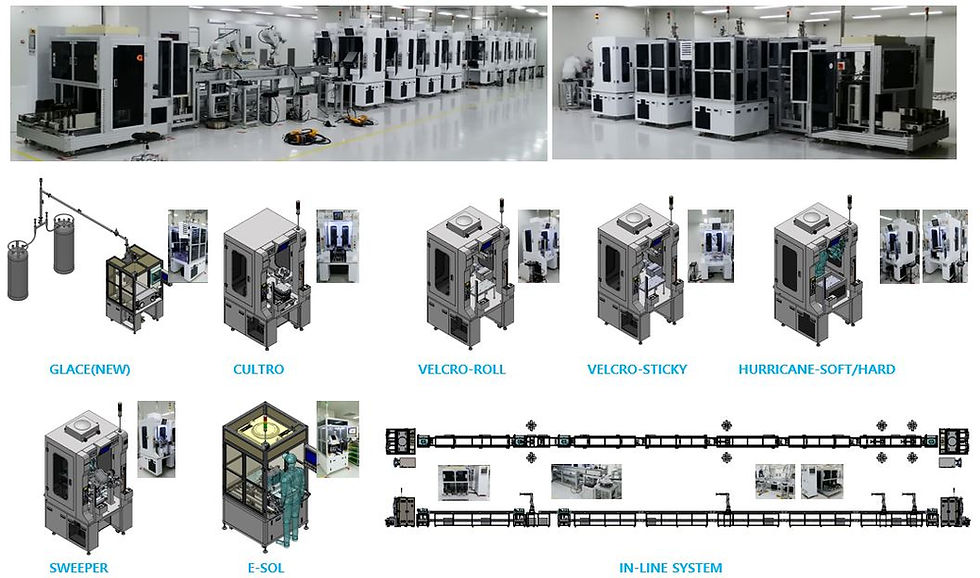

This is a cleaning system developed to clean very thin substrates (such as UTG and others) ranging from 30um to 100um. It moves away from the traditional ultrasonic dipping method and uses a sheet-by-sheet cleaning process. The system can remove various floating or stubborn contaminants, and depending on the configuration of the cleaning zone, it can also remove organic contaminants. The input and output can be configured as an in-line logistics system.

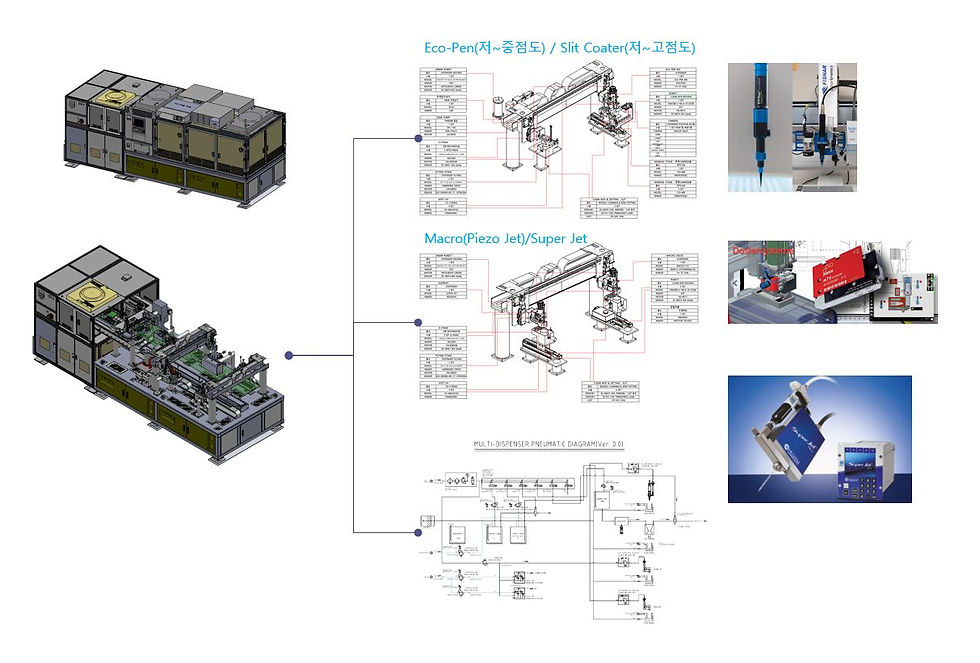

Slit Coating / Inspection / LED UV

The system is configured to perform Vision Alignment, Slit Coating, and UV Curing sequentially in a single piece of equipment. Panels are supplied via an in-line logistics system by a robot, and the system also includes automatic coating thickness inspection.

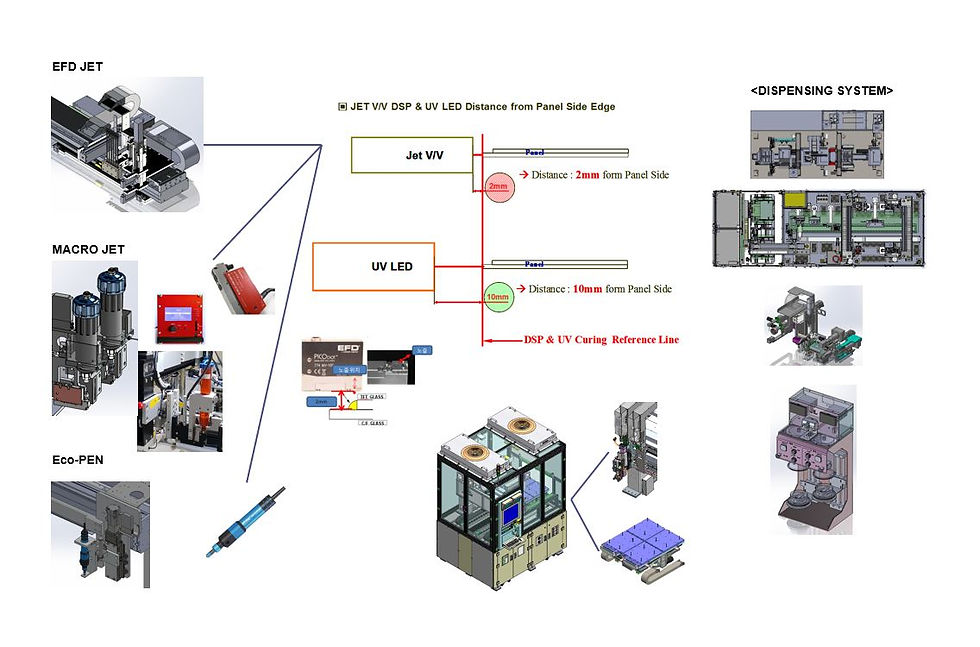

Precise Micro Pump

To be able to develop a high-precision dispensing pump that can handle a wide range of viscosities, from low-viscosity materials like Photo Resist and BM (3.5 to 20 cps) to high-viscosity materials like OCR (15,000 to 20,000 cps).

Slit Coating Nozzle

Design and manufacture nozzles, which are crucial components for coating quality, to match the characteristics of the coating solution. This ensures coating uniformity and facilitates maintenance by incorporating a lip.

OUR MISSION

Perfect Repair Through Vision Inspection

.png)

_edited.jpg)

IT Repair Technologies with AI Vision Inspection

AgTech with Repair

Cleaning for Improvement

-

Modernization and technological innovation support for agricultural product processing facilities

-

Streamlining agricultural product distribution linked with product data

-

Agricultural product quality and safety management - linking with traceability systems

-

Resolving information asymmetry

-

Data business linked with online platforms

-

Providing and processing big data in conjunction with the expansion of distribution channels

Cleaning for Improvement

Slit Coating with Vision Inspection

Cleaning for Improvement

Smart Welfare Society

WHO WE ARE

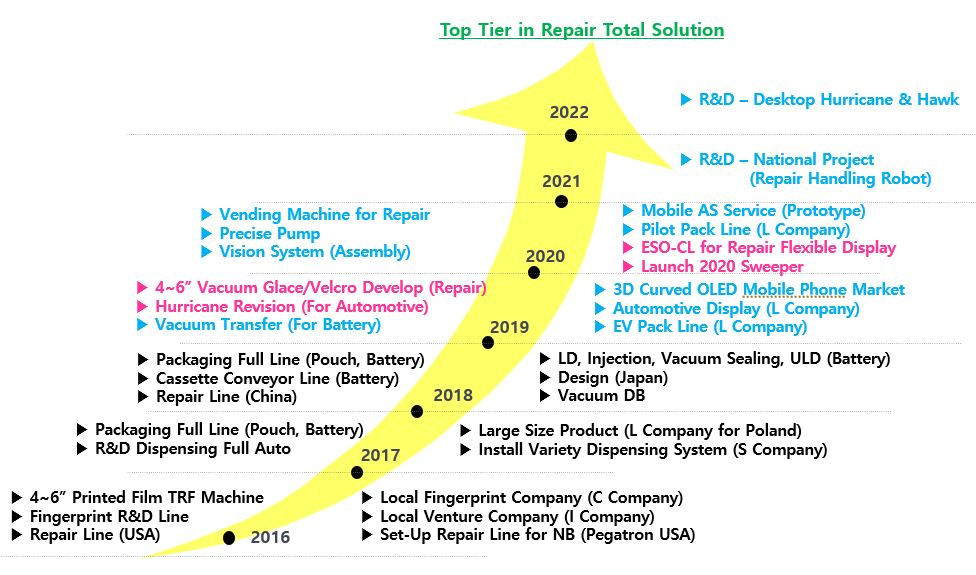

Meet the History

TSM R&D Co., Ltd., established in 2011 and converted to a corporation in 2015, has a long history of providing repair services to Korean, Chinese, and Taiwanese companies in the Repair sector. Now, by integrating AI vision inspection technology, the company is pursuing expansion of its repair business into the Agritech sector based on its proven technology, moving beyond IT.